Description

Neitabond NANO coated aluminum composite panels are produced using a new and exciting NANO PAINT technology. A clear water soluble NANO coat is applied over our 2 or 3 coat PVDF coating to enhance the performance of the coated panels weatherability and durability resulting in longer color and gloss retention. The nano coating changes the molecular structure of the paint by sealing off any air gaps between connecting molecules making the surface both lipophobic and hydrophobic (oil and water Resistant) This prevents dirt, water, permanent spray paint, carbon monoxide, grease, oil or any foreign particles to penetrate through the paint surface. In addition, the NANO coating is a non-toxic, VOC EMISSION FREE coating system, which makes the surface self –cleaning and repellent to air-borne pollutants.

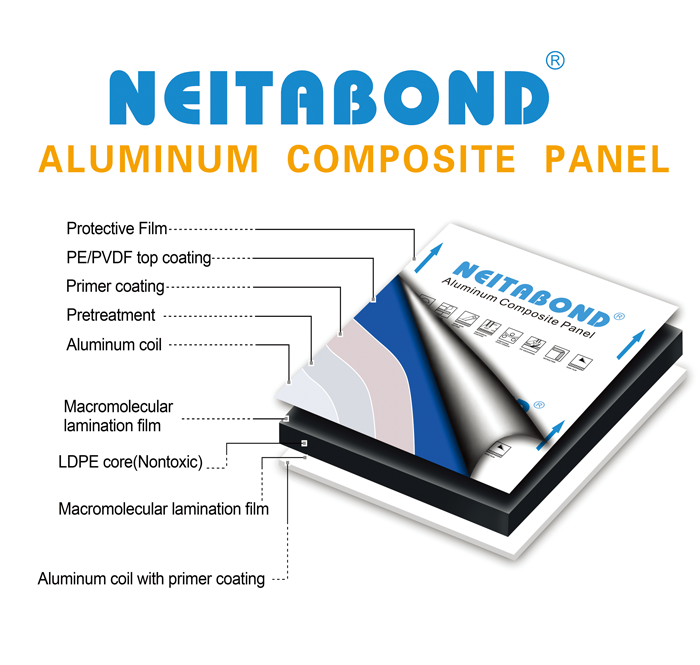

Raw material:

Base material: high strength aluminum alloy sheet

PE core material: non-toxic low density polyethylene

Surface coating: NANO PVDF coating

Back coating: primer coating

Product properties

Excellent easy-cleaning

Pollution resistance

Oil resistance

Good friction resistance

Strong acid & alkali resistance

Outstanding weather resistance

APPLICATIONS:

Wall curtain, Cladding and Facade

Roof edges and Parapet wall

Dado, Separation wall and Partition

Interior wall, Ceiling, Bathroom, Kitchen and Balcony

Advertisement boards, display platforms and signboards

Column covers and Beam wraps

Industrial materials, vehicle and boat materials

| Aluminum alloy | AA1100 AA3003 |

| Aluminum skin | 0.21mm,0.30mm,0.35mm,0.40mm,0.45mm,0.5mm |

| Panel thickness | 3mm,4mm,5mm,6mm |

| Panel width | 1220mm,1250mm,1500mm |

| Panel length | 2440mm,3050mm,4050mm |

| Surface treatment | NANO PVDF |

| Colors | 70 colors, special colors available upon request |

| Customers size | accepted |

| GLOSSY | 30%-50% |

Panel width: ±2mm

Panel length:±3mm

Panel thickness: ±0.2mm

Panel diagonal: ≤5mm

Aluminum sheet thickness: ±0.02mm

| Description | Test standard | NANO PVDF |

| Thickness of coating | PVDF paint≧34um | 35um to 37um |

| Coating flexibility (T-bend) | Polyester paint≥2T | 2T |

| Color different | ΔE≦2.0(follow color sample) | ΔE<2.0 |

| Pencil hardness | ISO 15184:1998 Section 10 | 5H |

| Chemical resistance | 5%HCI or 5% NaOH test in

24 hours -No change |

No change |

| Coating adhesion | ISO 15184:1998 Section 6 | The edges of the cut are

completely smooth ,none of the square of the lattice is detached. |

| Resist solvent | No change for 200 times(MEK) | No change |

| Boiling water resistance | EN438-2:2005 Section 12 | Rating 5,no visible change.

Average change of mass: 0.08%;Average change of thickness:1.36% |

| Peeling strength/

stripping strength |

BS EN319:1993 | 2.4N/mm2 |

| Impact test for paint | ISO6272-1:2002 Section 8 | The coating not crack or peel after

2kg weight ball dropped from 1.5m height |

| Abrasion resistance

(L/Mil) |

ISO7784-2:1997 Section 8 | The abrasive rubber wheel:

Taber H-22; the cycles number:100; the mean loss mass:91mg |

| Temperature resistance | EN438-2:2005 Section 19 | Rating 4, change of gloss only |

| Coefficient of linear

Thermal Expansion |

ISO11359-2;1999 Section 7 | 1.3×10-4K |

| Detergent resistance (3%) | ASTM D2248 | No change |

| Humidity Resistance

(3000hrs,100%RH,100°F) |

ASTM D2247 | No change |

| Salt spray resistance

(3000hrs,5% salt) |

ASTM B117 | No change |

| Resistance to Staining | EN438-2:2005 Section 26 | Rating 5,no visible change |

Avis

Il n’y a pas encore d’avis.